Auto flattening test system

This system adopts advanced technology of flattening test a wide speed range of electro-hydraulic proportional valve and computer digital control etc., to form full digital closed loop speed control system. The whole process can automatically and accurately measure and control the flattening machine loading and unloading test, wide control range, all the operation of the keyboard. Various test parameters are controlled, measured, displayed, processed and printed by the computer. High integration, easy to use and reliable.

The main components of this test system:

a. Digital electro-hydraulic servo controller

b. Test software

c. Force and displacement sensor (strain gauge)

d. Hydraulic actuator

e. Electro hydraulic proportional valve

f. Hydraulic source

g. Test specimen (of a test vehicle)

Digital electro-hydraulic servo controller using AOWEI’s self-developed FirstTestB digital servo controller, full digital closed loop control. The interface with the computer in this system is the computer plug-in (PCI computer bus design method).

The test software used in this system is AOWEI’s Test_DSC3.0 dynamic test software independent research and development. integrated AOWEI’s controller product suite perfect integration, configuration and convenient use.

Auto flattening test system

Functional characteristics

* Hydraulic cylinder drive loading.

* Load closed loop and displacement closed loop, control mode optional.

* Hardware and software double overload protection and limit function.

* Real time measurement and display of load and deformation.

* Ramp wave loading, sinusoidal loading, custom loading.

* Load displacement and load can be set.

* Hand operated box for easy positioning adjustment.

* Computer control, real-time rendering curves, storage data.

* Test data and curves can be maintained, output and print.

* History can query, call.

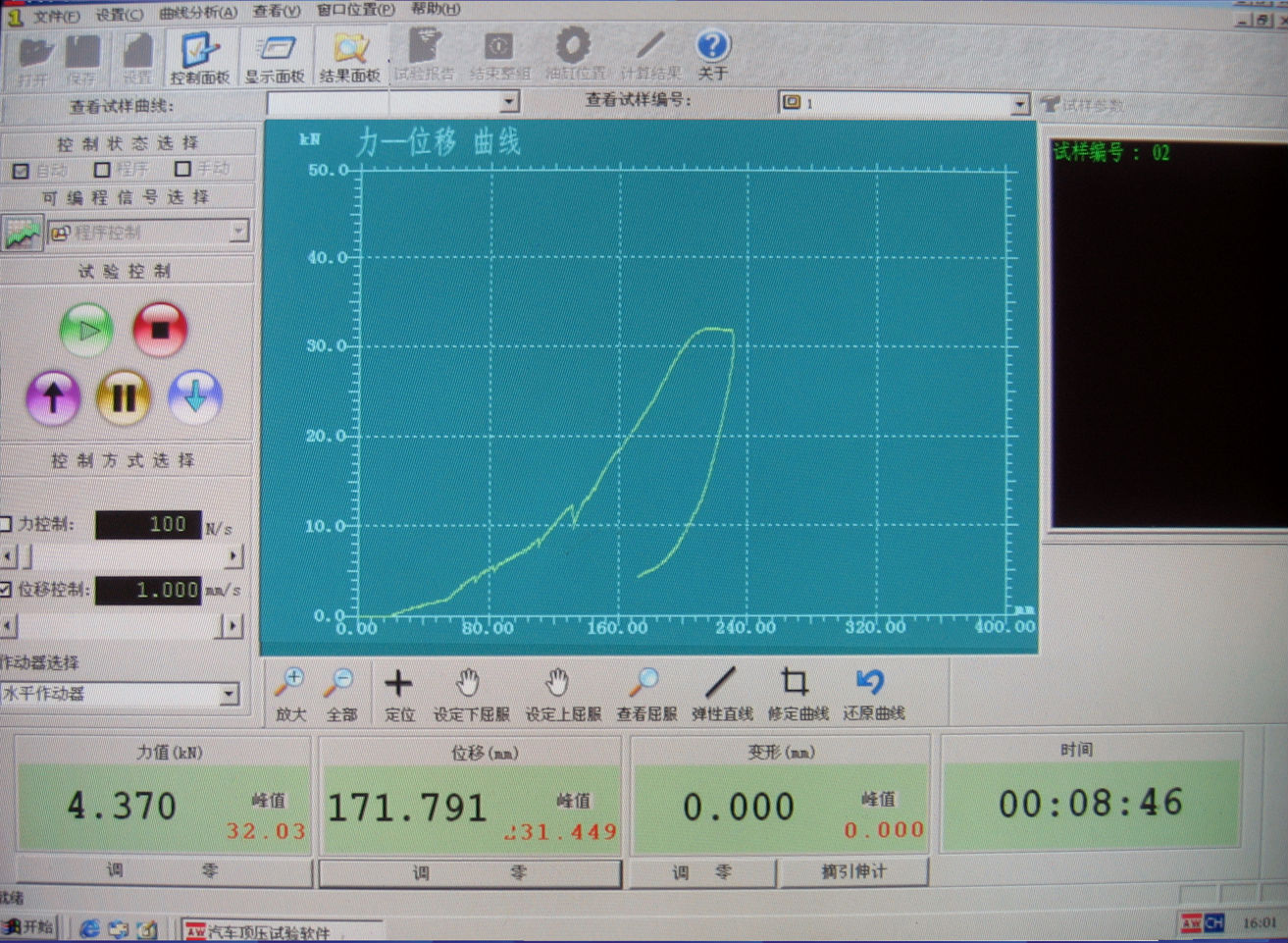

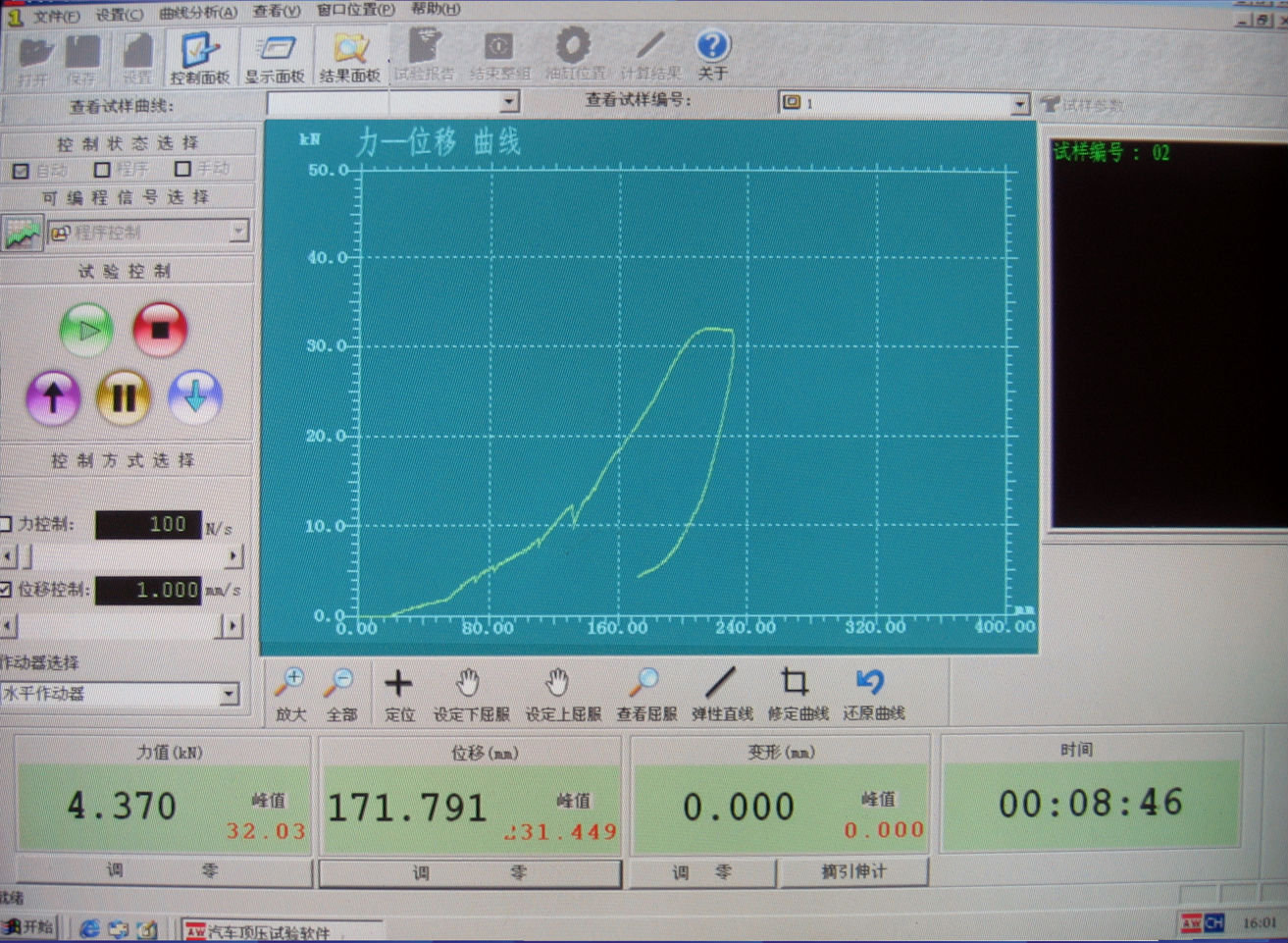

Force-displacement curve

Force-displacement curve

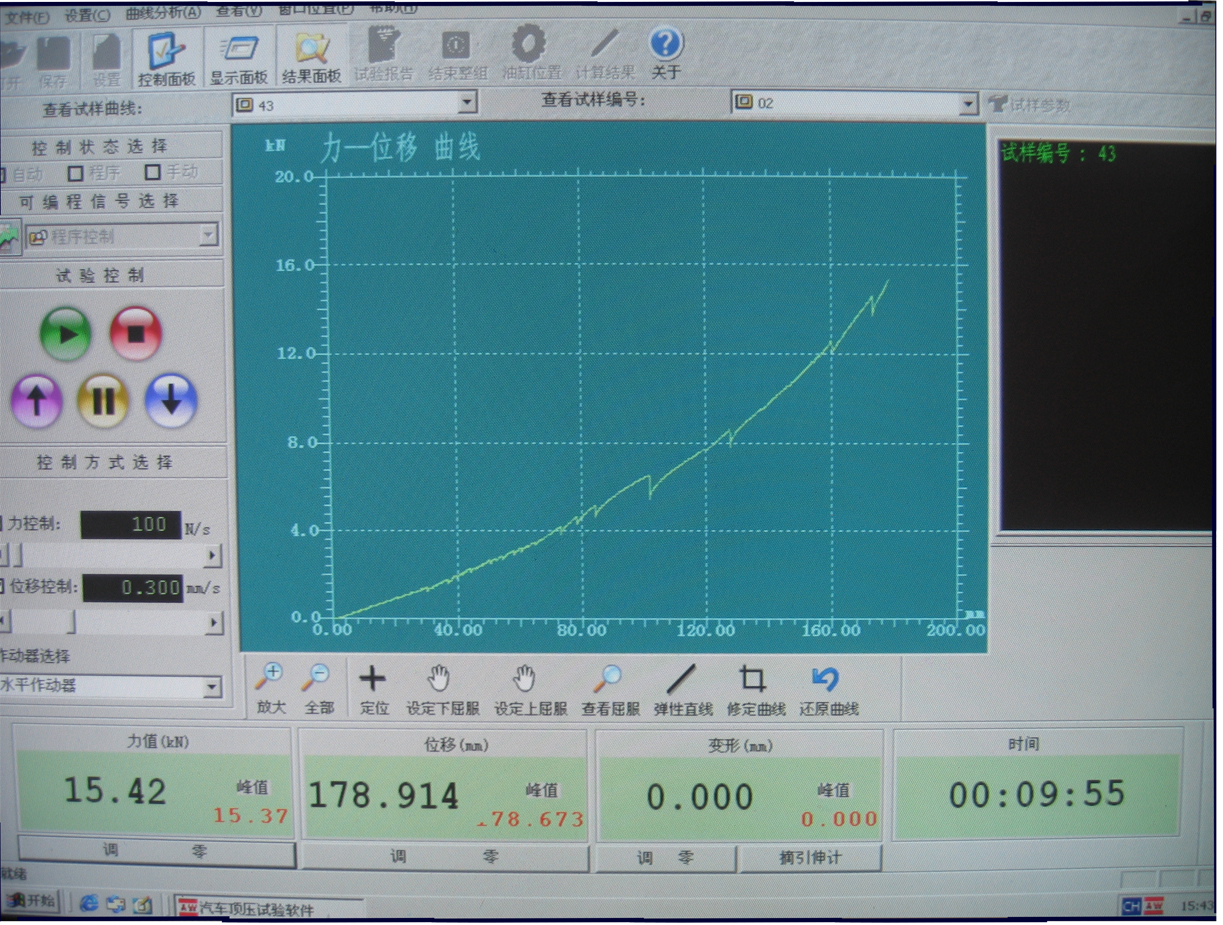

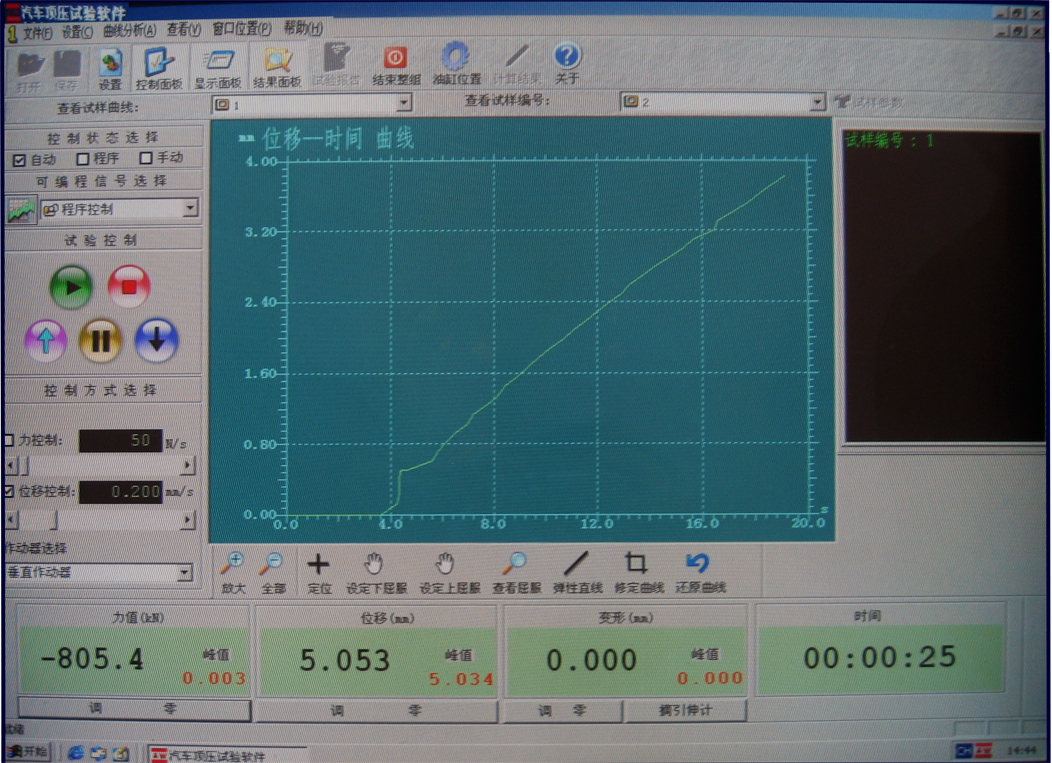

Displacement-time curve

Based on standard

◎ [ GB26134—2010 Top compression strength of passenger car ]

Automobile manufacturing enterprise

Automobile manufacturing enterprise