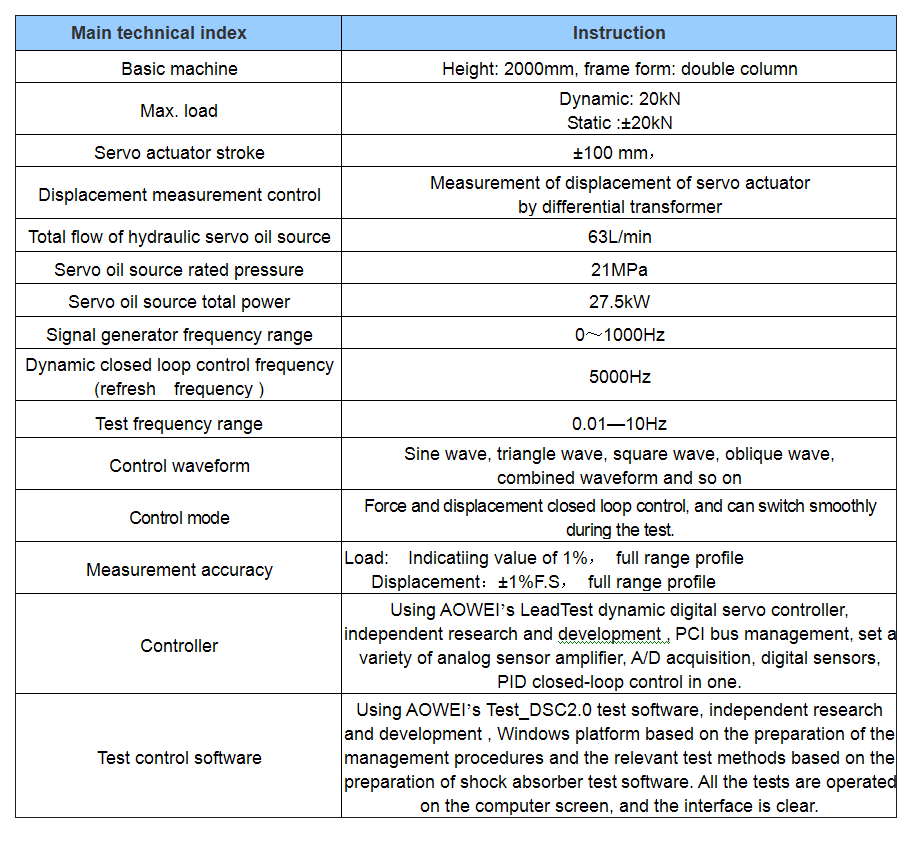

Automotive damper test system

The main components of this test system: mainly by mechanical loading system, hydraulic power system, computer measurement and control system composed of several parts.

Mechanical loading system: mainly by the base, loading frame, beam, column, lifting cylinder, test fixture, etc..

Hydraulic power system: mainly by the servo hydraulic oil source, servo actuator, servo valve, control valve group, pipeline systems and other components.

Computer measurement and control system is mainly composed of computer, Orville full digital servo controller, Orville dynamic test software, data acquisition card, load sensor, displacement sensor (LVDT) etc..

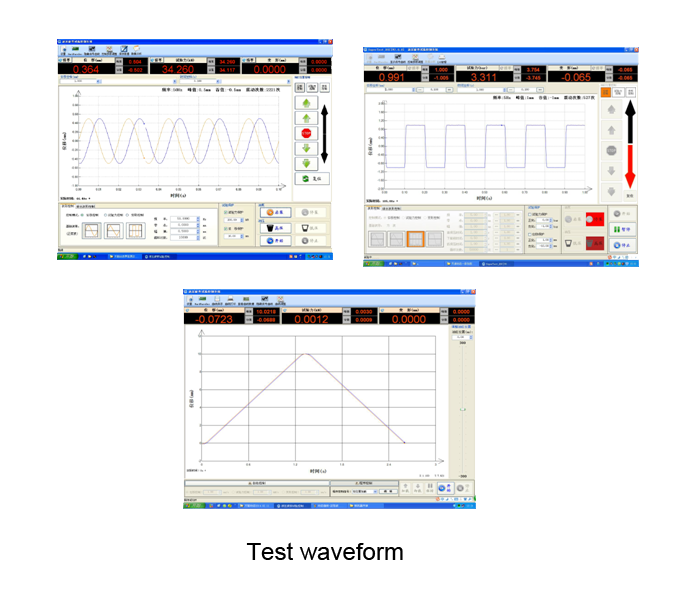

The test system is controlled by computer, and the electro-hydraulic servo actuator can realize fast and high response. According to the corresponding test standard, the test can be done:

a. Damping test: Determination of shock absorber damping coefficient, damping angle, etc.;

b. Power test: draw the damper indicator diagram;

c. The speed characteristics of the test: at different loading speed of the shock absorber at each speed point temperature;

d. Conventional fatigue test: measuring the fatigue life of shock absorber;

e. Road spectrum test: the safety and comfort of the car.

Functional characteristics

* Controller for the company's own R & D, convenient for users to test the upgrade, after-sales service in a timely manner.

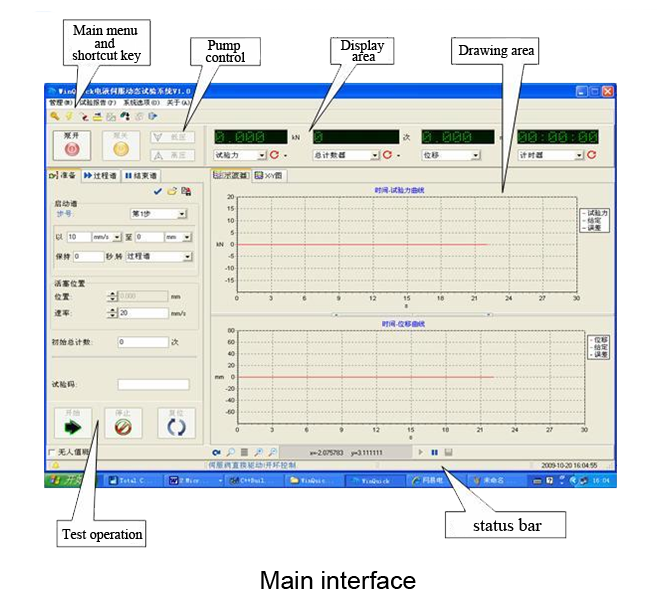

* Computer plug-in (i.e. computer bus design) digital closed loop control.

* With a computer control to complete the entire test process, the operation is completed by the keyboard and mouse.

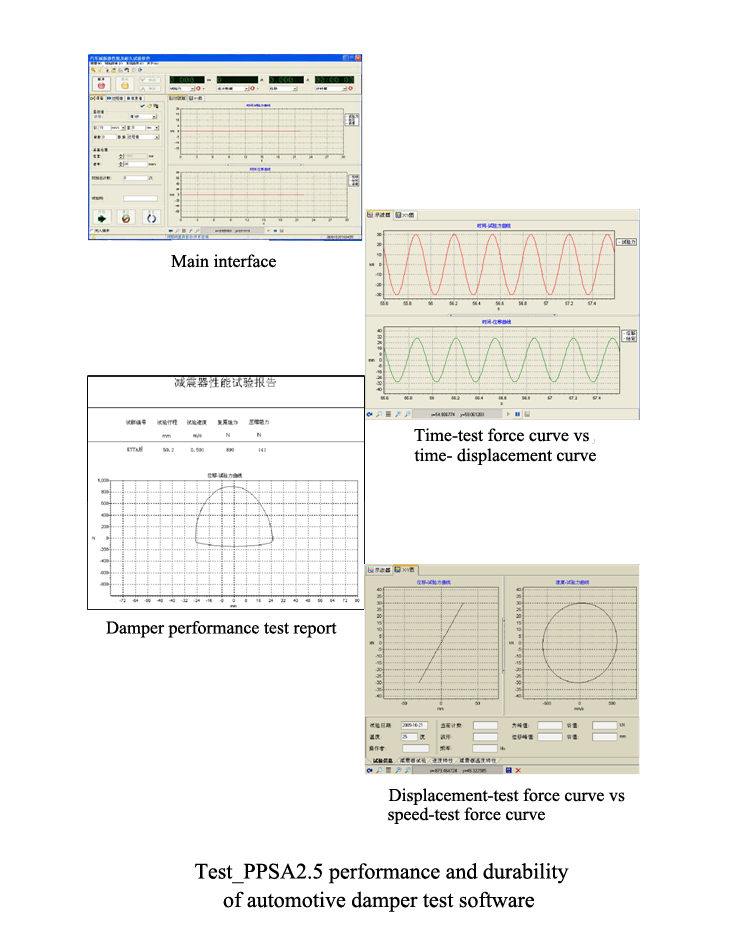

* Can run the software platform of the computer closed-loop system, accurate control, self calibration, automatic zero adjustment, automatic reset, fast and accurate data transmission. With peak and amplitude phase compensation function, the measurement of the linear correction, PID computer control.

* The sampling frequency of the system is as high as 5kHz. Can provide analog and digital input and output interface, rich data acquisition and graphics display.

* Perfect hydraulic control function: to control the pump station on / off, high / low voltage switch, etc..

* Perfect protection and alarm function: high temperature, low level of oil tank, oil filter blockage.

* The complete database software interface for users to use, software upgrades can only be sent by mail CD or E-mail.

* The perfect software self-test function, prompt the breakdown place, does not need the manufacturer to carry on the maintenance, only needs to replace the corresponding function card in the computer, the maintenance is simple and convenient.

* User optional environmental test device.

Based on standard

◎ Automobile industry standard [ QC/T545-1999 Test method for automobile cylinder shock absorber ]

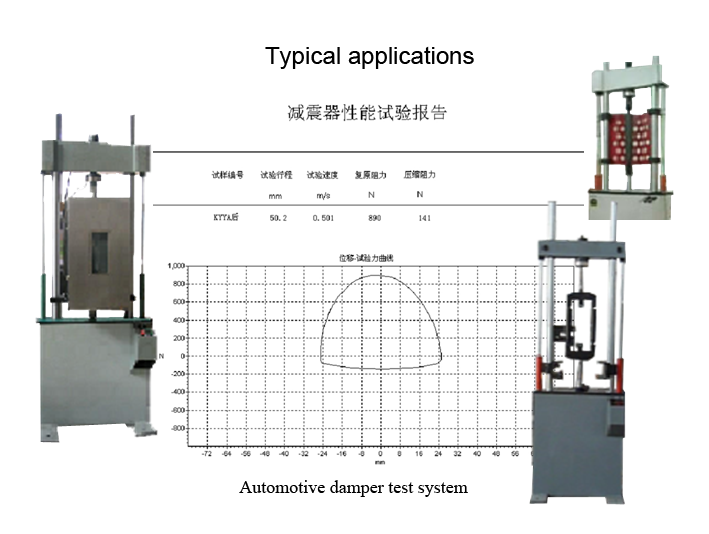

Automobile cylinder type damper

Automobile cylinder type damper