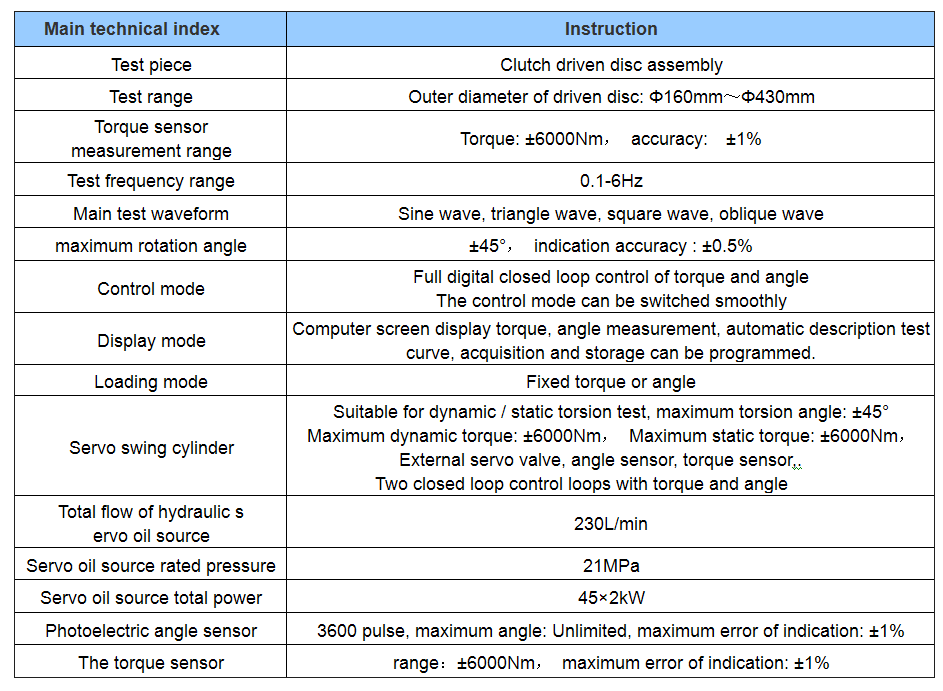

Electro-hydraulic servo clutch driven disc assembly torsional fatigue test bench

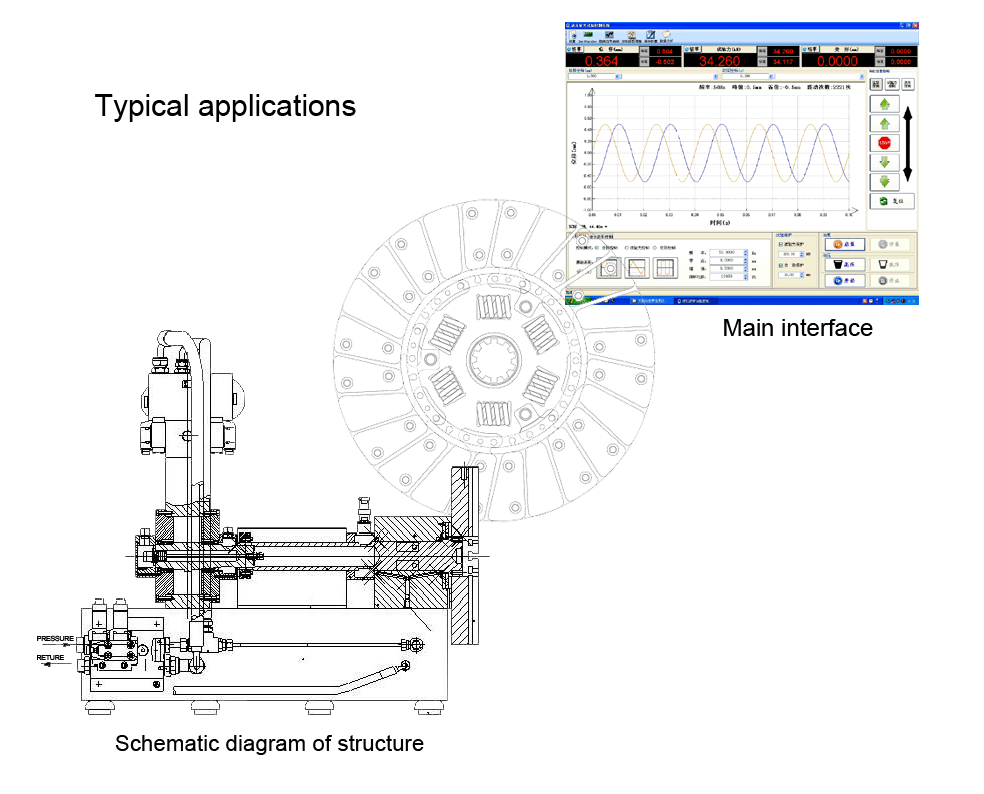

The test rig was subjected to dynamic torsion test with certain test torque or test angle, test frequency and signal type. During the test, the new test parameters can be modified without interrupting the test. At the same time, it can also be used for the control of static torsion test, such as constant test torque rate or constant angular rate test, all kinds of long time holding test or oblique wave combination test. The test bench’s main part: mainly including: basic machine, servo torsional actuator (servo swing cylinder), servo oil source, torque sensor, full digital closed-loop measurement control system, computer software system components.

Basic machine: frame, platform, torque measurement mechanism, simulation, simulation of flywheel pressure plate etc..

Hydraulic servo oil source pump set: imported high quality low noise pump group.

Full digital closed-loop measurement control system: composed of AOWEI’s LeadTest digital dynamic servo controller. Can automatically and accurately measure and control test machine, unloading and loading test of the whole process, dynamic test can be carried out, and static test also.

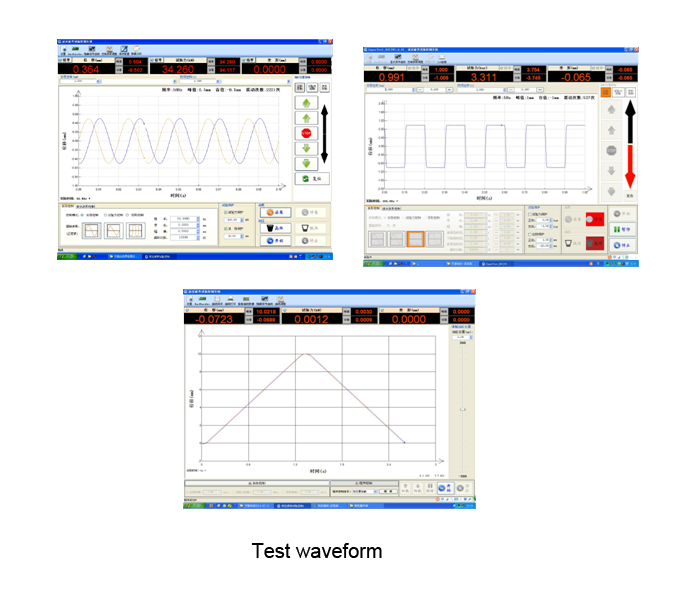

Computer software system: using AOWEI’s Test_DSC2.0 dynamic test software with independent research and development. C# language programming, powerful, all the test through the computer screen operation, clear interface to facilitate the establishment of the test, set up and operate. Computer screen can display test curve and test parameters, such as the curve of torque / angle-time curve, torque-angle curve and various test parameters (torque, angle) of the peak value and real time value (such as actuator rotation angle during adjustment) , the control error value, the given value, and special value etc..

Test item Load mode

* Test torque * Setting torque loading

* Test angle * Set angle loading

* Test times

* Torsional frequency

Functional characteristics

* Controller for the company's own R & D, convenient for users to test the upgrade, after-sales service in a timely manner.

* The controller is a computer management, according to different requirements of the test configuration of different dynamic measurement and control card, convenient for later test expansion.

* Computer plug-in (i.e. computer bus design) digital closed loop control.

* With a computer control to complete the entire test process, the operation is completed by the keyboard and mouse.

* Signal generator frequency: 0~1000Hz.

* Sample and update frequency: 5000Hz。

* Control waveform: sine wave, triangle wave, Fang Bo, oblique wave, and combined waveform, and the external signal input.

* Control mode: it can realize the dynamic and static closed loop control of the test torque and torsion angle and the smooth switching of the control mode.

* Perfect hydraulic control function: to control the pump station on / off, high / low voltage switch, etc..

* Perfect protection and alarm function: high temperature, low level of oil tank, oil filter blockage.

* The complete database software interface for users to use, software upgrades can only be sent by mail CD or E-mail.

* The perfect software self-test function, prompt the breakdown place, does not need the manufacturer to carry on the maintenance, only needs to replace the corresponding function card in the computer, the maintenance is simple and convenient.

* During the test, the dynamic torque, test frequency, fatigue and so on are displayed in real time.

* With a variety of display, such as the number of tests, the peak value of the various test parameters / real-time value, torque - angle curve, torque / angle - time curve, etc.. And with all kinds of test parameters exceed the limit, set the automatic stop or alarm function.

Based on standard

◎ [ QC/T27-2004 Bench test method of automobile clutch ]

Auto parts enterprises

Auto parts enterprises