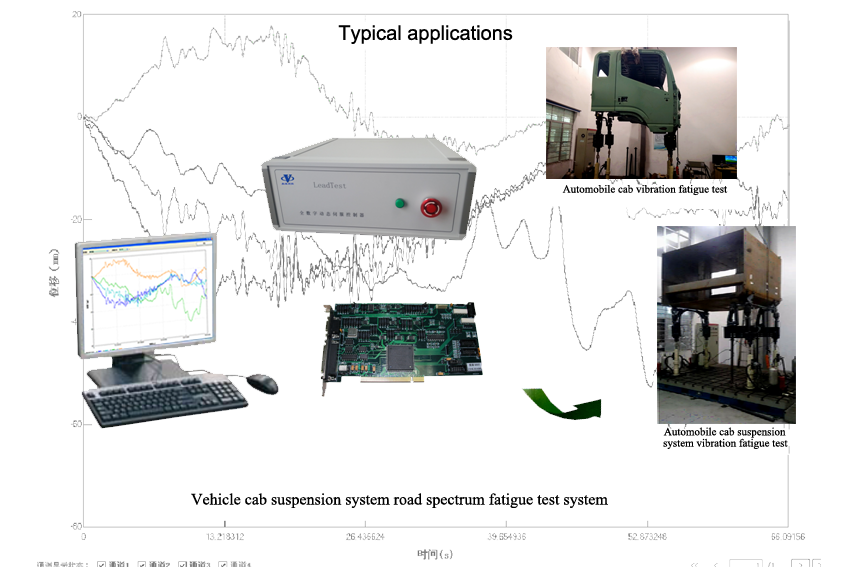

Vehicle cab suspension system road spectrum fatigue test system

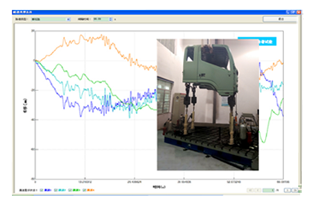

Vehicle cab suspension system road spectrum fatigue test system is application extension of indoor road simulation test. The test system can provide the necessary test data for the dynamic characteristics of the suspension and the measurement of ride comfort. The test system uses mature dynamic testing technology, the use of modular, standardized, modular design means to implement the system design and manufacture, to ensure the reliability of the system, advanced and practical. The test system uses 4 servo hydraulic actuators to realize the road spectrum fatigue test of the whole vehicle, cab, body and suspension parts.

The system is flexible, which can be used to carry out the four channel coordination loading test, and can also be used for single channel loading test, the user can configure the test fixture according to the test requirement. It is used for the endurance strength test of the automobile parts under the simulated working conditions, and the loading test of other parts, and simulates the various space movement postures.

The main components of this test system:

a. Full digital dynamic servo controller

b. Test software

c. Sensor

d. Servo hydraulic actuator

e. Servo valve

f. Servo hydraulic source

g. The test piece (the test vehicle or parts)

Full digital control system adopts AOWEI’s independent research and development of LeadTestB digital dynamic servo controller, full digital closed loop control. The interface between the computer and the computer is used in the system, which is the way of network communication and data exchange.

The system’s test software uses independent research and development of dynamic test software, integrated perfectly with AOWEI’s controller product suite, configuration and use is very convenient.

Functional characteristics

Main technical points of full digital multi channel coordinated loading servo controller:

* The number of control channels: 4, each channel includes the test force and displacement of the two dead loop control loop, with the control mode without interference smooth switching function.

* Signal generator waveform: sine wave, triangle wave, square wave, road spectrum test wave.

* Limit parameter setting function; phase control accuracy: 2°

* Other necessary I/O input / output units: four analog inputs, four analog output interface; four digital inputs, four digital output interface (optional)

* Two stage servo valve drive unit.

* Remote hydraulic pump control function.

Technical index

* Configure the number of site control interfaces: 4

* Maximum dead loop control data refresh frequency: 6kHz

* Controller A/D, D/A resolution of 16 bits

* Signal frequency range: 0.001Hz~25Hz

* Control precision: the typical precision of static control precision is 0.3%FS, and the typical value of dynamic control precision is generally 0.5%FS

* Number device capacity:108

Automobile driving and train driving simulator

Automobile driving and train driving simulator