Electro-hydraulic servo fatigue testing machine upgranding

The original test machine has been upgraded and the performance is stable and reliable for a long time. The AOWEI’s full digital control system after the transformation, the test machine can complete a variety of test items and corresponding test function, significantly enhance the test precision can be ensured, the economic benefits have increased significantly,

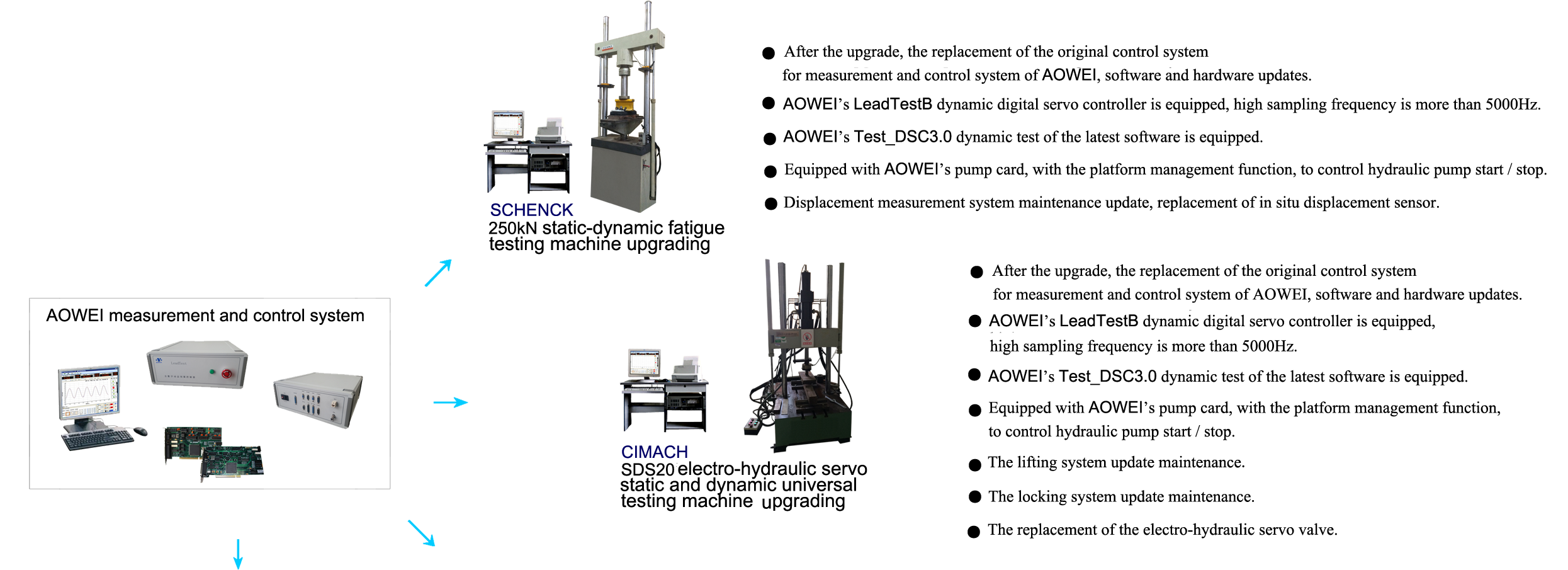

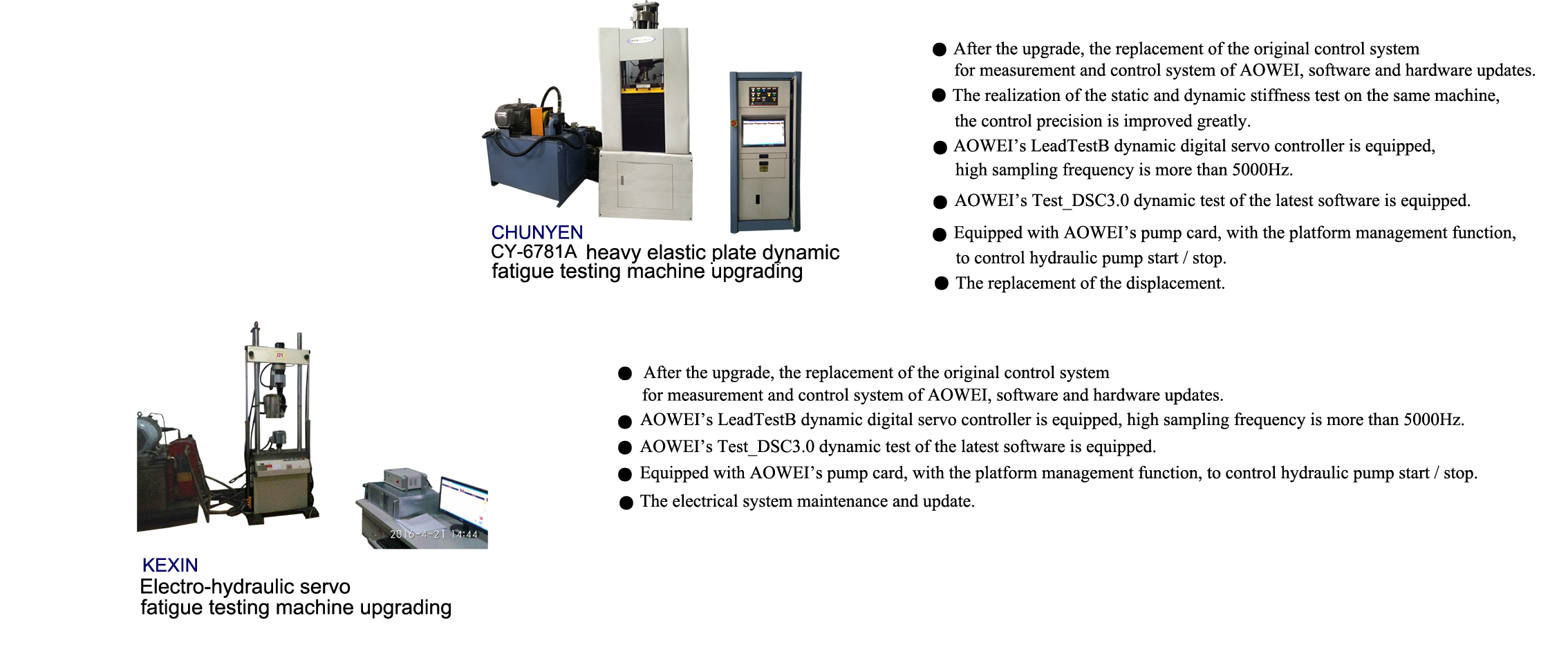

Typical applications

After upgrading the electro-hydraulic servo fatigue testing machine for high-end brand, AOWEI company has accumulated abundant experience, through using morden AOWEI’s measurement and control technology, drive technology and test software, to be able to update the material testing machine from multiple brands to meet the latest scientific and technological equipment. In the new transformation of the equipment, the use of mature technology has been used in practical parts to upgrade, in line with the requirements of modern technology.

AOWEI company can also be upgraded to the following brand testing machine (including: measurement and control system upgrade, hydraulic source transformation and upgrading of environmental test etc.):

MTS

INSTRON

Zwick

Shimadzu

Saginomiya

SUNS

HUALONG

Functional characteristics

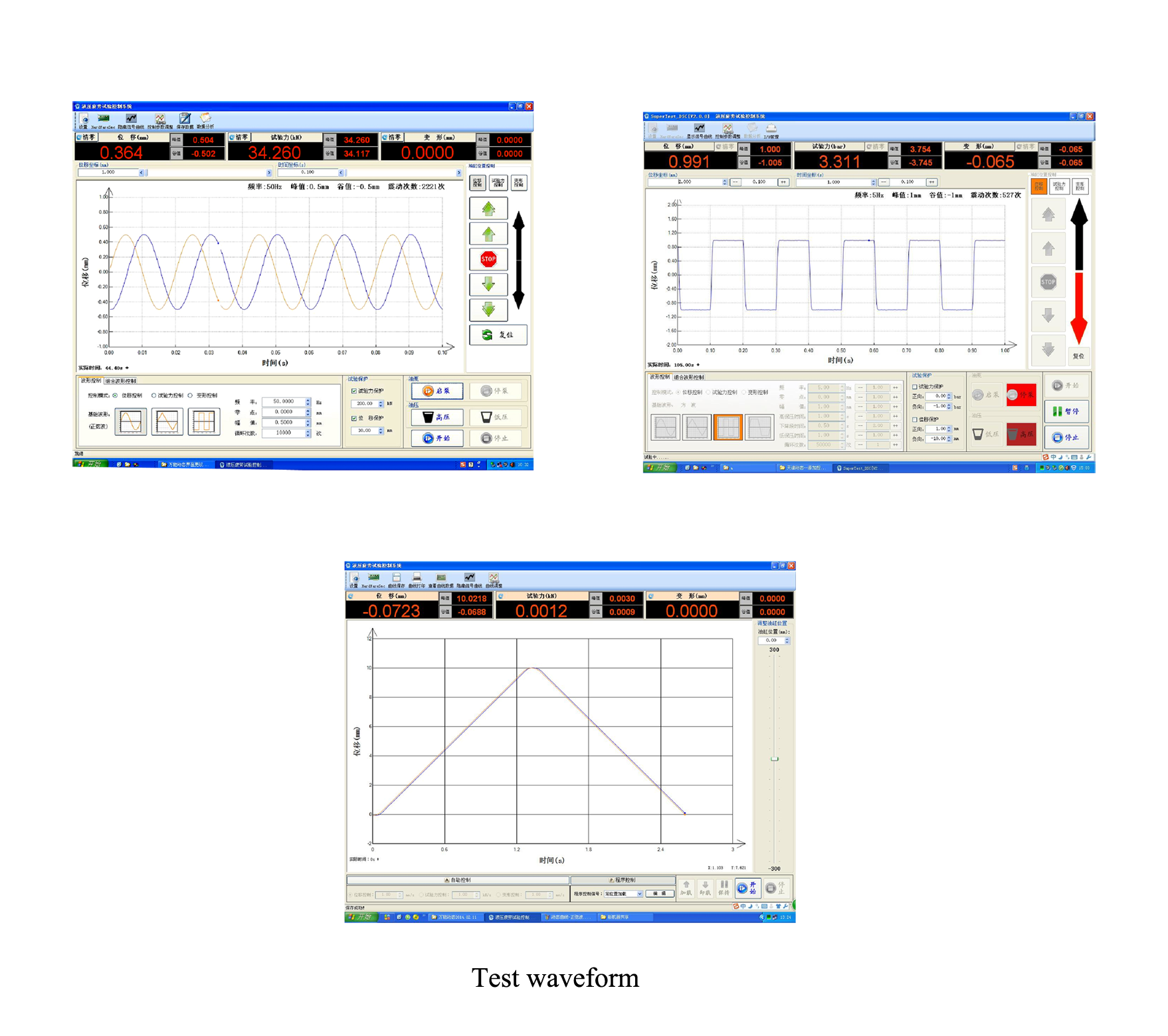

* The replacement of the original control system, all digital dynamic servo controller configuration Ovid, to form a new closed-loop electro-hydraulic servo control system. Its characteristic is:

a. The system adopts modern all digital control technology, which can realize multi channel control.

b. The system has the function of complete hardware and software, wide scope of application, easy to master, easy to operate, high control precision, stable operation, high degree of automation and low cost.

c. To achieve stable and reliable control and testing software standardization, seriation, standardization, product of the ideal, it is suitable for electro hydraulic servo test machine and the upgrading of the new factory testing machine control system optimization.

d. Stable and reliable performance, ensure that the test system for a long time and reliable work.

e. The technical level and performance index of the system are in the leading position inChina, which has reached the international advanced level.

* AOWEI’s test software adopts windows and windowsXP platform and Chinese interface.

* After the transformation of the original test machine, it can greatly improve the test ability, precision, automation and prolong the service life of the test machine.

Based on standard

◎ GB/T2611 [ General technical requirements for testing machines ]

◎ GB/T16826 [ Electro hydraulic servo universal testing machine ]

◎ GB/T3075 [ Metal axial fatigue test method ]

◎ JB/T9397 [ Technical requirements for tension and compression fatigue testing machine ]

◎ GB/T228 [ Test method for tensile testing of metallic materials at room temperature ]

Aerospace

Aerospace