Horizontal tensile testing machine upgranding

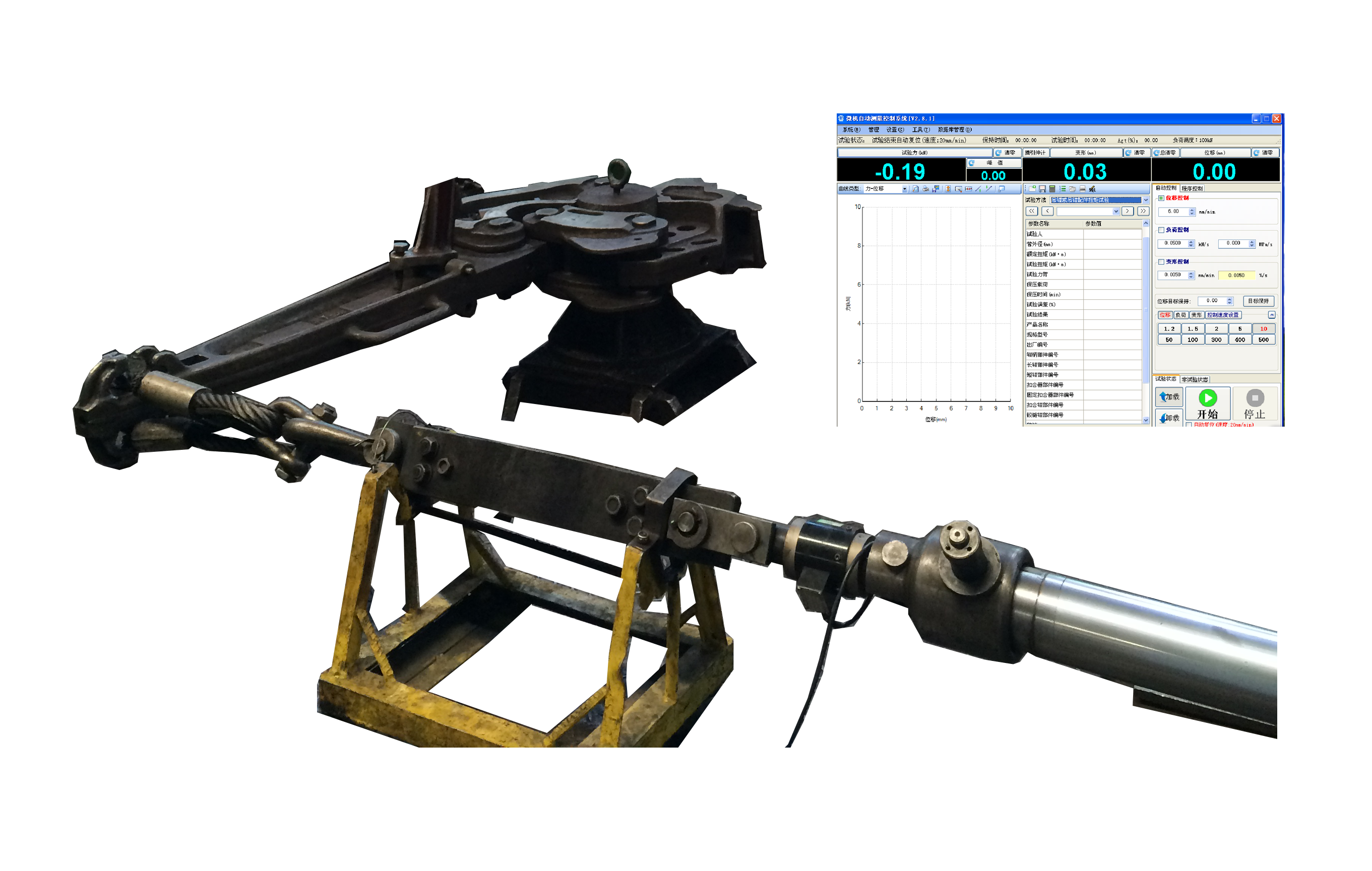

Horizontal tensile testing machine adopts whole frame welded steel frame structure, mainly used for testing the tensile strength of steel wire rope, wire, hook, chain and other soft firmware. The equipment is mainly composed of three parts: host system, oil source system and control survey. Computer screen display test force and test curve, according to the experimental requirements of the automatic processing of test data.

The tensile testing machine is a practical example of horizontal tensile testing machine. In order to further meet the tongs for quality control and traceability of the relevant requirements, the user puts forward relevant technical transformation of existing tongs tensile testing machine, its main purpose is to meet the requirements of the standard, to achieve the preservation of tongs test record and fast query.

Measurement and control system of hanging clamp tensile testing machine transformation uses AOWEI’s self-developed FirstTest digital servo controller. FirstTest test software can control electro-hydraulic proportional valve, using C# language programming, powerful function, all tests through the computer screen operation, clear interface to facilitate the establishment of the test, set up and operate.

Based on the existing tension device, increase tension tests, feedback hardware, and the design and development of special software to save, analysis of the test data, and automatically generate the test report and pull hanging clamp, according to the test record of the saved user information given fast query.

Force measuring method: load sensor

Typical applications

Hanging clamp tensile testing machine upgrading

Horizontal tensile testing machine upgrading

Horizontal tensile testing machine upgrading

Functional characteristics

* After the transformation of the measurement and control system to meet the "stability, security, maintenance, standard operation, adaptability," and other aspects of the requirements, the operator can operate with the mouse, easy to learn.

* Computer plug-in (i.e. computer bus design) digital closed loop control. With a computer control to complete the entire test process, the operation is completed by the keyboard and mouse.

* Accurate measurement, complete functions, high reliability, simple operation, easy to use.

* The system has the function of overload protection: when the actual test force exceeds the set value (that is, according to the test input torque and arm into the 5%), alarm system, and stop loading.

* According to the test when the received power and force data, convert torque, numerical test equipment should display the final output torque.

* The test process should have at least two kinds of control modes: "space adjustment" and "programmable automatic loading". The space adjustment control should be "fast" and "rewind" function.

* The equipment has the servo system, can carry on the real-time compensation, maintains the test load the stability, may realize the progressive loading function, the loading step programmable.

* The measurement of inertia force of test machine by using load sensor.

* The displacement displacement sensor two between the jaw displacement value displayed by the computer screen.

* Main contents of printing: test results (rated torque, test torque)

* The results of the test automatically determine whether or not qualified

* Switchable display multiple test curves:

Stress-strain curve,Force-deformation curve,Force displacement curve,

Force-time curve, Deformation-time curve, Displacement-time curve

* The test force can be controlled, and the test force can be maintained.

* It can be used to control the rate of deformation, and the deformation can be maintained.

* Displacement rate control can be carried out, and the displacement can be maintained.

* During the experiment, the control speed and control function can be switched to each other.

* Can set the control parameters to achieve the automatic operation of the program, you can carry out triangular wave, sine wave, square wave and other low cycle and the user design a variety of combination waveform test.

* As a single or group sample test.

* With the protection of the whole machine and sample fracture protection function.

* Modular design for easy maintenance.

* Advanced digital electro-hydraulic servo proportional valve as a control element, anti pollution ability, can achieve long-term failure free operation.

* Digital pulse width modulation technology, the full digital closed-loop servo control.

* Perfect software self-test function, suggesting that there is a failure, the need for on-site maintenance, only the replacement of the corresponding functional card can be.

* The complete database software interface for users to use, software upgrades can only be sent by mail CD or E-mail.

Main interface

Based on standard

◎ GB/T3075 [ Metal axial fatigue test method ]

◎ JJF1103-2003 [ Evaluation of computer data acquisition system for universal testing machine ]

◎ GB/T16825-1997 [ Test of tensile testing machine ]

Oil drilling

Oil drilling