DGS-Multi channel coordinated loading test system

DGS- Multi channel coordinated loading test system adopts AOWEI’s LeadTest full digital dynaminc servo controller, to compose the full digital closed loop M&C system. The test system can be used in the axial, horizontal or any angle of the test system, including large parts, parts of the static low cycle and tension compression fatigue test. The test system consists of a plurality of servo actuators, a multi-channel servo controller, a servo hydraulic source and a loading frame. Each actuator can operate independently, but also a number of coordinated operation.

Functional characteristics

* Servo valves, sensors and other key components using the top products, so that the system has high reliability.

* The actuator is designed with low friction and high performance.

* It has the close loop control of force, displacement and deformation.

* Load waveform: sine wave, triangle wave, trapezoidal wave, Fang Bo, oblique wave, combined waveform, Cheng Xubo, random wave, spectral input, etc..

* Static control, dynamic control.

* Multi channel decoupling control, phase control and automatic amplitude adjustment.

* Intelligent compensation technology: the effect of automatic compensation of inertia force on force measurement.

* Site management functions: to control the pump station to open / stop, high / low voltage start switch (optional HSM proportional output).

* Perfect self inspection, protection and alarm function.

* The large flow servo oil source is adopted in the form of multi stage pumping station, and each sub pumping station can work independently or in parallel.

Technical index

* Number of channels: 16 (expandable)

* Measurement accuracy: ±1%

* Control precision: ±0.5%

* Oil source flow: 400/min(Maximum reachable 1200/min)

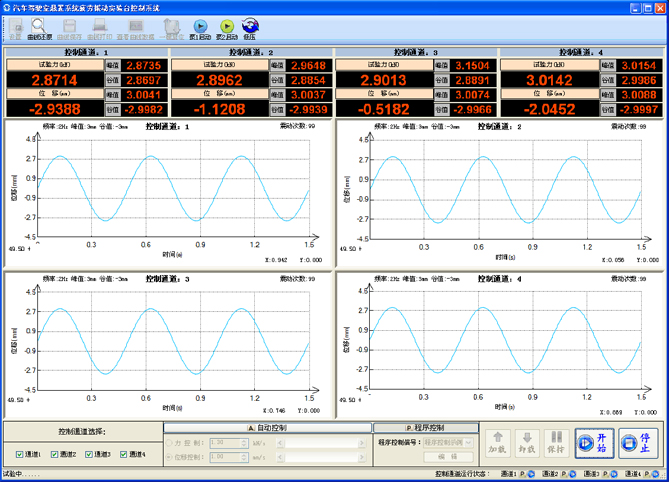

Multi channel coordinated loading test

Main interface

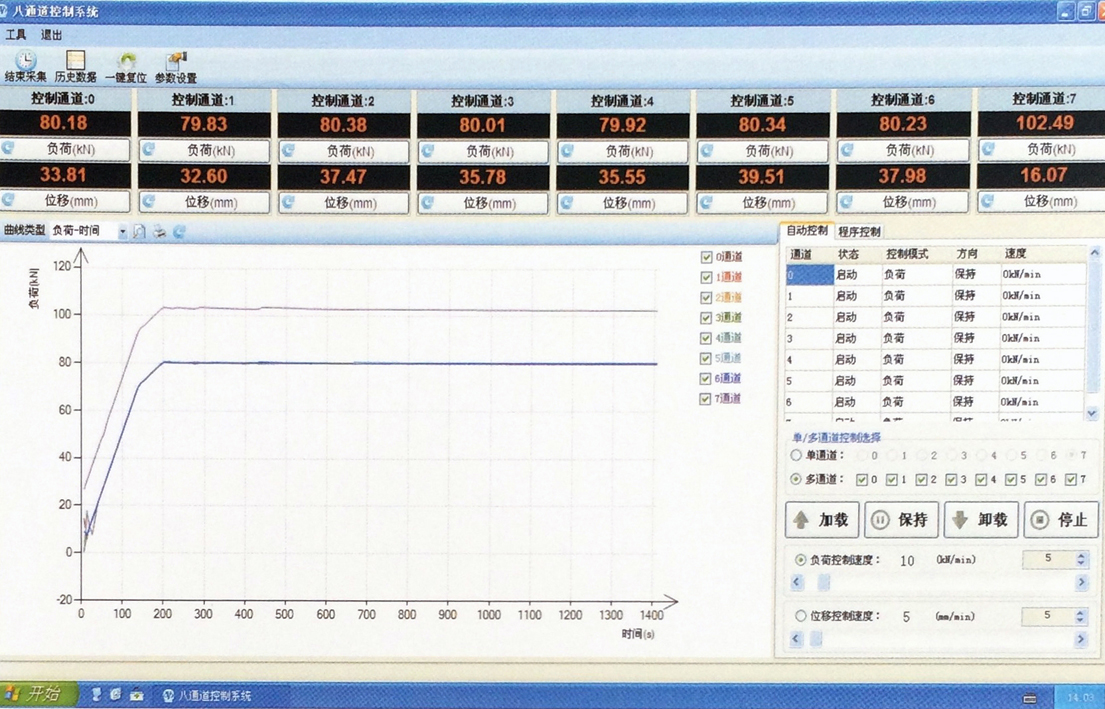

Eight channel control system

Based on standard

◎ GB/T2611 [General technical requirements for testing machines]

◎ GB/T16826 [Electro hydraulic servo universal testing machine]

◎ GB/T3075 [Metal axial fatigue test method ]

◎ JB/T9397 [Technical requirements for tension and compression fatigue testing machine]

◎ GB/T228 [Test method for tensile testing of metallic materials at room temperature]

Aerospace

Aerospace