Model PCA-8005 dynamic servo M&C board

This product adopts the computer plug-in design, PCI bus management, Set a variety of analog sensor amplifier, A/D acquisition, digital sensor acquisition, PID closed loop control in one.

Functional characteristics

Servo control

Ø Three closed loop control modes of force, displacement and strain.

Ø Closed loop control frequency:5000Hz(update frequency)

Ø Control accuracy:±0.1%

Ø Signal generator frequency:0~1000 Hz

Ø Control waveform:Sine wave, triangle wave, trapezoidal wave, Fang Bo, oblique wave combination waveform, and the external signal input.

Ø Automatic regulating function with precise amplitude.

Ø Can control the servo motor, servo valve, proportional valve, etc..

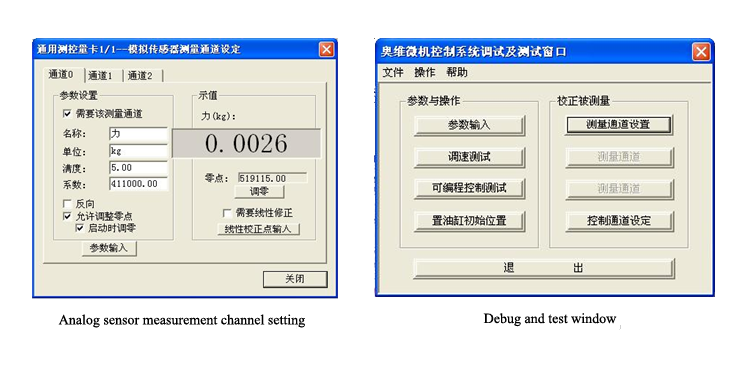

3 way analog sensor measurement

A. 2 way bridge sensor measurement, can also be measured with a ±5V large signal sensor.

Ø Bridge Precision power supply for:±5V Dual power supply

Ø Sampling frequency:10kHz

Ø Effective sampling resolution:±50000 yard

Ø Signal pass band:>1kHz

Ø Measurement accuracy:be better than 1/1000(Indication value),1/10000(full scale)。

B. 1 wayl analog measurement channel——LVDT(displacement transducer)measurement,can also be measured with a ±5V large signal sensor.

Ø Sensor driven——for 4 kHz, ±3V AC dual power drive

Ø Sampling frequency:10 kHz

Ø Effective sampling resolution:±100,000 yard

Ø Signal pass band:>10~1000 Hz

Ø Measurement accuracy:be better than 0.2%

4 way digital sensor measurement

A. 3 way measurement channel,digital sensor measurement of AB phase and phase difference of 90 degree for photoelectric encoder, grating ruler, etc.

Ø 4 frequency multiplication phase discrimination.

Ø Input signal:2MHz。

B. 1 way digital measurement channel,measurement of MTS and other digital hysteresis telescopic sensors。

Control output: three types of control output(Optional)

(1).±10V analog output

Ø Using 16 bit DAC

Ø Output frequency:>4 kHz

(2).Frequency output:

Ø Using frequency and direction signals

Ø Output frequency:0~10 kHz。

(3) Pulse width signal (PWM) output:

Ø Cycle:1ms

Ø pulse width:resolution is 10nS

Oil source control auxiliary control and protection alarm function

A. Auxiliary control.

Ø Oil pump stop, start.

Ø High pressure and low pressure conversion of oil source system pressure.

B. Protection and alarm function.

Ø Oil temperature.

Ø Lower tank level.

Ø Oil filter blocking.

Electro-hydraulic servo dynami- static fatigue testing machine

Electro-hydraulic servo dynami- static fatigue testing machine