PLD- electro-hydraulic servo dynamic-static fatigue testing machine

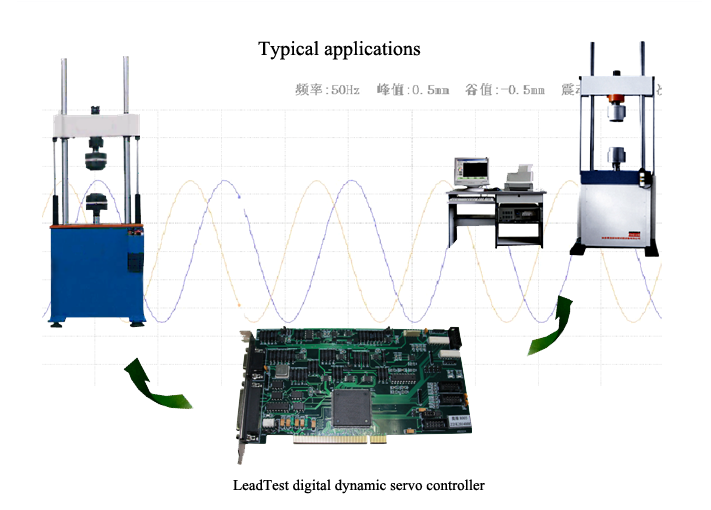

PLD- electro-hydraulic servo dynamic-static fatigue testing machine adopts AOWEI’s LeadTest full digital servo controller to compose the full digital closed loop measurement and control system, can automatically and accurately measure and control test machine, unloading and loading test of the whole process. The utility model can be used for dynamic test and static test, a high performance testing machine.

PLD- electro-hydraulic servo dynamic-static fatigue testing machine has the advantages of wide application range, high control precision, strong adaptability, flexible test method, wide frequency range and multiple test waveforms, to be suitable for complex test conditions. Configuring the corresponding software and hardware, it can expand the use range of users, to meet the test requirements of the new materials in the material science research, and is favorable to the improvement of the material test technology and the development of the test method.

PLD- electro-hydraulic servo dynamic-static fatigue testing machine’s main components:

a. Basic machine load frame

b. Servo hydraulic oil source

c. Full digital control system

d.testing software

e. Fixtures and accessories

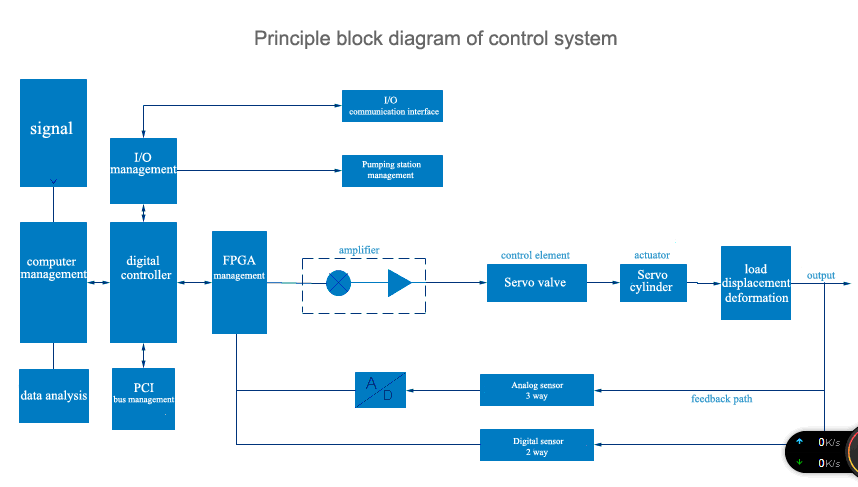

Full digital control system adopts AOWEI’s independent research and development of LeadTest digital dynamic servo controller, its internal use of modular control, all operations and settings are achieved by the system control software to provide users with a simple and reliable operating environment.

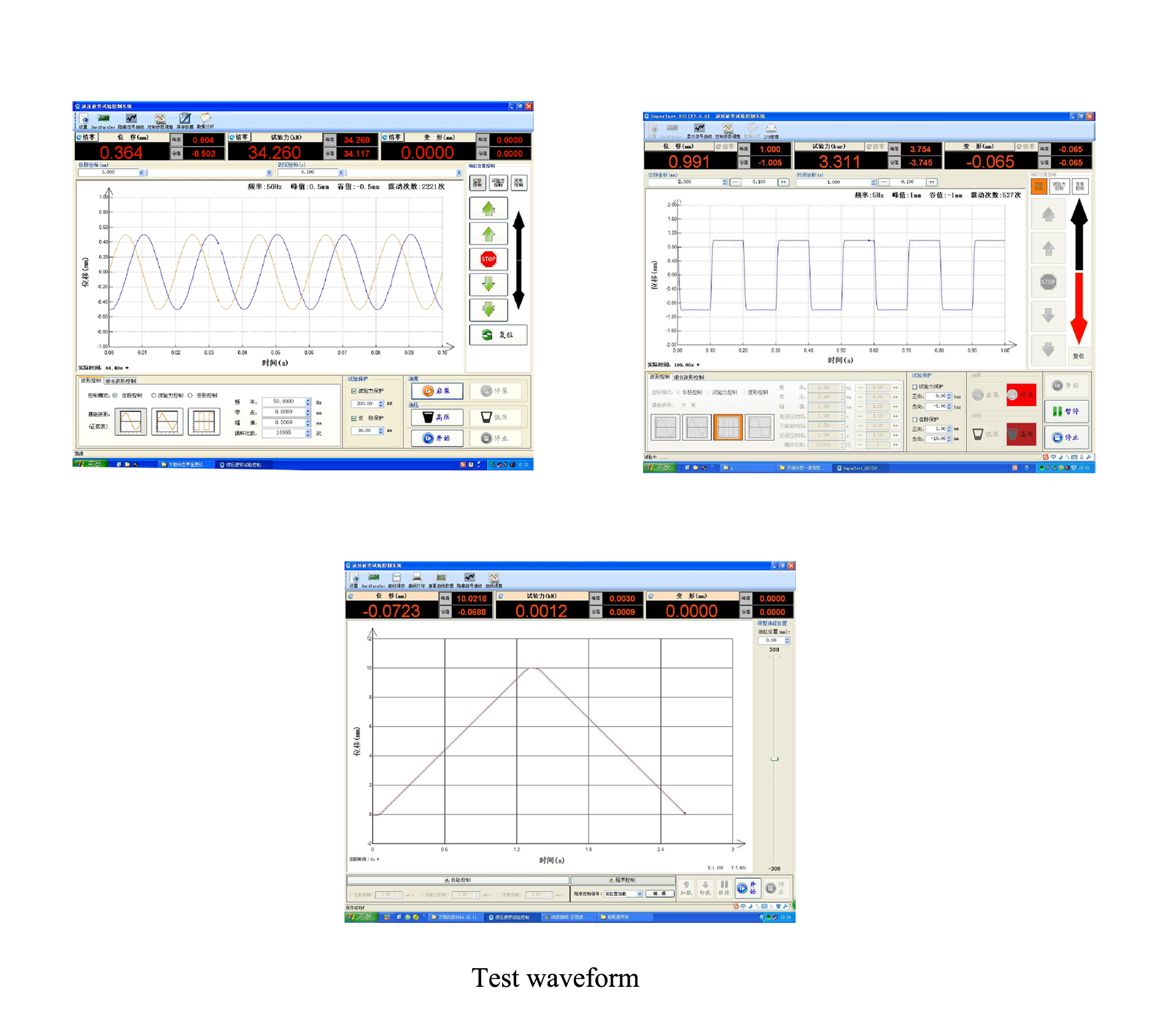

Test software adopts AOWEI’s independent research and development of Test_DSC3.0 test software, all experiments through the computer screen operation, clear interface to facilitate the establishment of the test, set up and operate.

Main test functions

Fatigue test—— complete zero crossing load test:

*Equal amplitude *Variable amplitude * Low cycle fatigue * High cycle fatigue

Static mechanics test—— can be used to test the static mechanics of various materials and components:

* Stretching * Compress * Bend

Fracture mechanics test——It can be used not only for prefabricating crack test but also for fracture test:

* Fracture toughness * Fatigue crack growth * Crack propagation * Plane strain fracture toughness of metallic materials KIC * Ductile fracture toughness of metallic materials JIC

Component testing—— Static and dynamic test of parts:

* Durability, strength and physical properties of parts and components

Environmental testing——The configuration of various high temperature furnace and environment box, fixture and extensometer, high temperature mechanical testing can simulate actual materials or components and under extreme conditions:

* Fatigue test of composite materials * High temperature fatigue * Stretching

Thermal mechanical fatigue test——The allocation of all kinds of high temperature furnace, fixture and extensometer can satisfy the thermal mechanical fatigue test.

Functional characteristics

* High rigidity load frame and low friction actuator ensure the system performance and make the system suitable for dynamic and static test.

* Load frame installation without special foundation.* The hydraulic servo oil source pump group adopts imported high quality low noise pump group.

* Servo actuator adopts dynamic high frequency, low friction, double acting piston structure, built-in displacement sensor.

* The servo valve is directly installed on the cylinder body, the cavity effect is small, and the natural frequency is high.

* Load sensor using HBM technology, the test force of inertia measurement, high precision, good reliability, can carry out the tension and compression test, lateral resistance is good; with 150% overload capacity.

* Computer plug-in (i.e. computer bus design) digital closed loop control.

* Control mode: load, displacement, deformation of three closed-loop control.

* With a computer control to complete the entire test process, the operation is completed by the keyboard and mouse.

* Perfect hydraulic control function: to control the pump station on / off, high / low voltage switch, etc..

* The complete database software interface for users to use, software upgrades can only be sent by mail CD or E-mail.

* Perfect software self-test function, suggesting that there is a fault, no need for on-site maintenance, only the replacement of the corresponding functional card can be, maintenance is simple and convenient.

* In the course of the experiment, the computer displays the dynamic load, the test frequency, the fatigue frequency and so on.

* With the test force - time, displacement - time, deformation - time, test force - displacement, test force - deformation curve and can be real-time switching curve type.

* Perfect data acquisition, storage, processing, printing, test data can be exported in word and excel format can be stored Access, pictures and other formats. Acquisition and storage can be programmed.

* Has any test point set and keep the function.

Based on standard

◎ GB/T2611 [General technical requirements for testing machines ]

◎ GB/T16826 [Electro hydraulic servo universal testing machine ]

◎ GB/T3075 [Metal axial fatigue test method ]

◎ JB/T9397 [Technical requirements for tension and compression fatigue testing machine ]

◎ GB/T228 [Test method for tensile testing of metallic materials at room temperature ]

Aerospace

Aerospace