SAW- electro-hydraulic servo rock three axis testing machine

SAM series electro-hydraulic servo rock three axis testing machine equipped with special AOWEI’s measurement control system. The machine is mainly used for uniaxial compression test, determination of uniaxial compressive strength, elastic modulus, tangent modulus and secant modulus, Poisson's ratio and softening coefficient; three axial compression test, and determination of three axial compressive strength, elastic modulus, shear strength and Poisson's ratio.

The following tests can be carried out with the corresponding accessories:

a) Uniaxial creep test or shear creep test: test the time effectiveness of rock deformation, rheological properties, long-term strength, the coefficient of viscosity.

b) Direct shear test: Determination of shear strength, shear strength, cohesive force, internal friction angle, shear strength.

c) Pore water pressure test: Determination of permeability

d) Splitting test: Determination of tensile strength

e) Variable angle shear test: Determination of shear strength at a certain angle

f) Fracture toughness test

g) Determination of fracture toughness

Main structure

SAM microcomputer controlled electro-hydraulic servo rock three axis testing machine is the most advanced and fully functional rock testing machine in china. It is composed of main unit, hydraulic system, measuring system and control system:

Basic machine:

The utility model is mainly composed of four upright posts or an integral frame type M type high precision mechanism, a pressure chamber with a three shaft, a supercharger, an oil cylinder loading mechanism and the like.

Hydraulic system:

It is mainly composed of servo hydraulic source, liquid filling hydraulic source, servo valve oil distribution system and electro-hydraulic servo valve.

Measurement system:

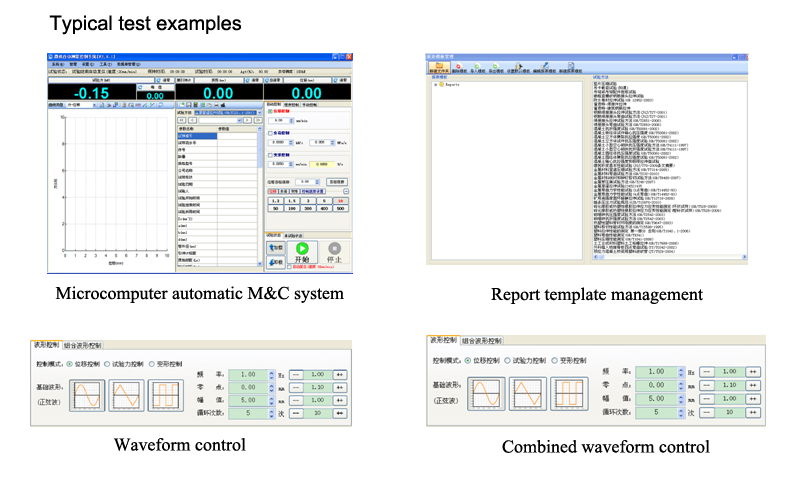

Mainly by the computer, console, load / displacement / strain measurement unit, measuring software, printers and other components.

Control system:

The cabinet (including installation of full digital control device and electric drive panel) PLC, power switch, air switch, relay etc..

Functional characteristics

* The use of advanced digital measurement and control technology and electro-hydraulic servo system and computer.

* The full closed loop control of three kinds of States, i.e., the test force (stress), deformation (axial strain, radial strain) and displacement (compression ratio), is realized accurately.

* Three kinds of full closed loop control mode can be used in the test process without mutual impact, smooth conversion.

* According to the program, the whole process of the experiment is controlled automatically, and the test state is displayed in real time, and the stress-strain curves of the rock specimen under uniaxial compression and three axial compression are plotted.

Based on standard

◎ GB/T50266 [ Standard for test methods of engineering rock mass ]

◎ SL264 [Code for rock test of water conservancy and hydropower engineering ]

◎ TB101115 [ Code for rock test of railway engineering ]

◎ JTG E41 [ Code for rock test of highway engineering ]

◎ GB/T3722 [ Hydraulic pressure testing machine ]

◎ GB2611 [ General technical requirements for testing machines ]

◎ GB/T16826 [ Electro hydraulic servo universal testing machine ]

Water conservancy and hydropower

Water conservancy and hydropower