Electro-hydraulic servo universal testing machine upgranding

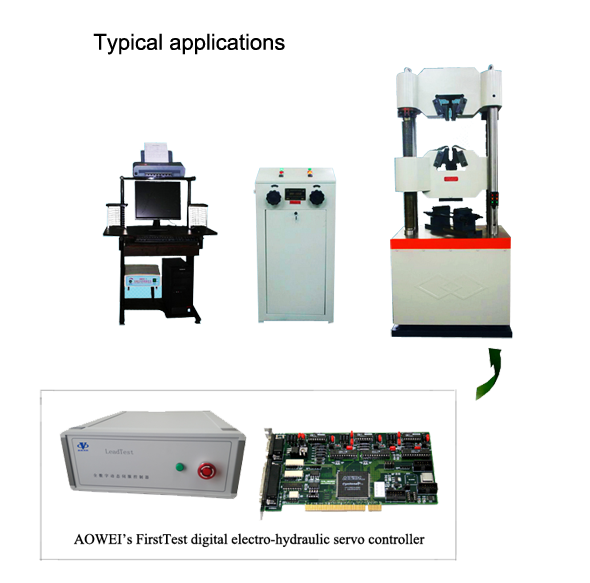

The electro-hydraulic proportional universal testing machine has been upgraded to the electro-hydraulic servo universal testing machine, which has the advantages of advanced technology, reliable operation and convenient maintenance. Equipped with AOWEI’s FirstTest digital servo controller, and equipped with AOWEI’s Test_JSC5.0 universal test software, the measurement and control system of the original test machine is upgraded to the advanced and mature electro-hydraulic servo control technology, the utility model provides a reasonable and feasible upgrade scheme for users, which is suitable for various types of hydraulic testing machines produced at home and abroad.

The main content of upgrade (optional):

a. Replacement of measurement and control system.

b. Replacement of software.

c. Hardware upgrade.

d. The replacement of force, displacement sensor, extensometer.

e. Hydraulic system maintenance transformation, replace not available components.

f. Basic machine transformation.

g. Measurement and control of electrical equipment installation, commissioning and calibration.

h. Field training.

Functional characteristics

The electro-hydraulic servo universal testing machine after the transformation of the original test machine has the following functions:

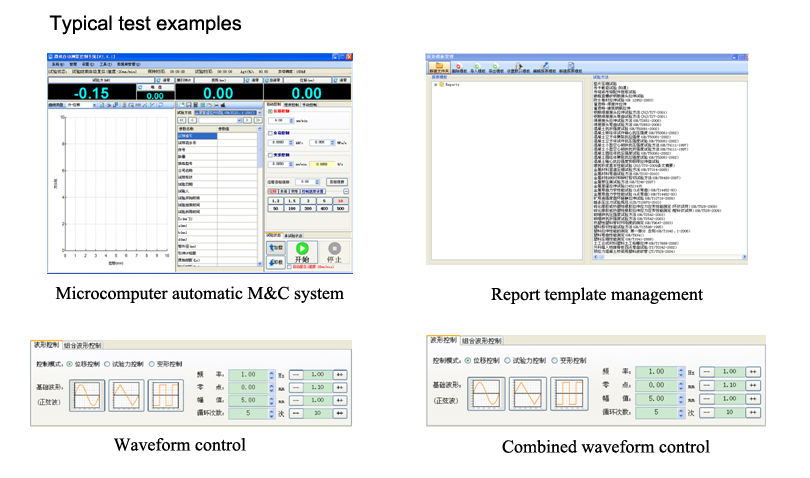

* Full digital three closed loop (load, displacement, deformation) measurement and control system.

* Intelligent test software, with the expansion of test functions to meet the latest test requirements.

* Perfect software self-test and self diagnosis function.

* Automatic zero adjustment, automatic calibration, continuous measurement.

* In the test process can be arbitrary smooth switching and maintenance.

* Data storage and curve amplification, can be displayed in the test process of different test curves, easy to observe.

* Protection functions: overload protection, limit protection, over current, over voltage, over temperature protection.

* All the test operation is controlled by keyboard and mouse, and manual control is left.

* Constant rate control of test force, deformation and displacement.

* Triangular wave, sine wave, Fang Bo and other low cycle and user design of various combinations of waveform test.

* The use of digital electro-hydraulic proportional valve as the control of the implementation of components, anti pollution ability, can achieve long-term failure free operation.

* Digital pulse width modulation technology, the closed-loop servo control system.

* Can be carried out group (batch) sample test and data processing.

* Hydraulic fixture key operation, reliable clamping, accurate test data.

* Can test room networking.

* The complete database software interface for users to apply, the software upgrade only send a CD or E-MAIL.

Based on standard

◎ GB/T228.1~201 [Test method for tensile testing of metallic materials at room temperature ]

Aerospace

Aerospace