High precision extensometer

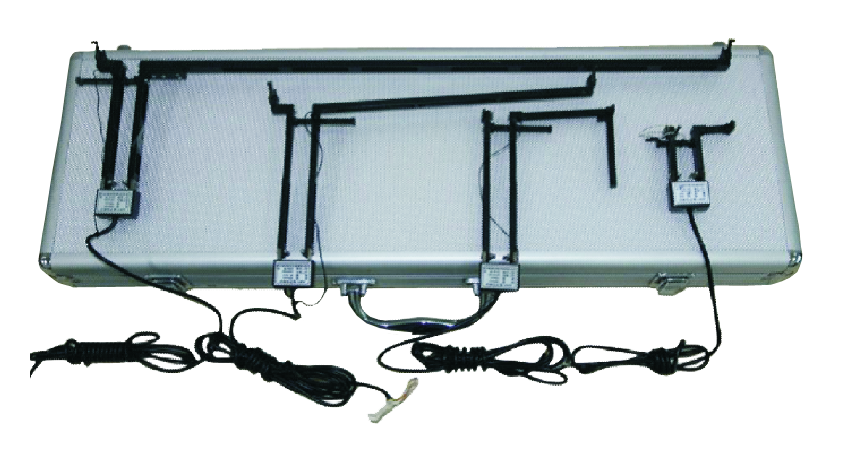

This series of resistance strain gauge is suitable for all kinds of specimen deformation measurement in range. It can be combined with measuring amplifier, strain gauge and other two meters to form the deformation measurement system, and the signal input to the computer or function recorder for data processing and drawing test curve, is a modern mechanical testing necessary measuring instruments.

Structure and working principle

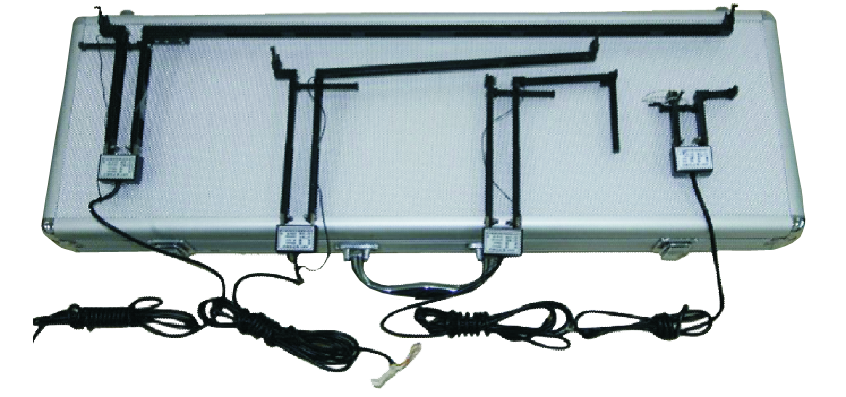

This series of extensometer mainly by cutting edge, spring clip, arm and elastic body. In the elastic body with a set of resistance strain gauge to form the whole bridge. When the test was carried out, the extensometer edge with the specimen deformation to generate a relative displacement, and also caused elastic body deformation, the strain gauge with composing whole bridge is output deformation signal. With the gauge positioning mechanism in the arm in front, with a pin to accurate positioning. The cutting edge is designed as a circular structure, The round specimen can be clamped and the flat specimen can be clamped, and the position can be changed at any time after abrasion, and the service life is prolonged.

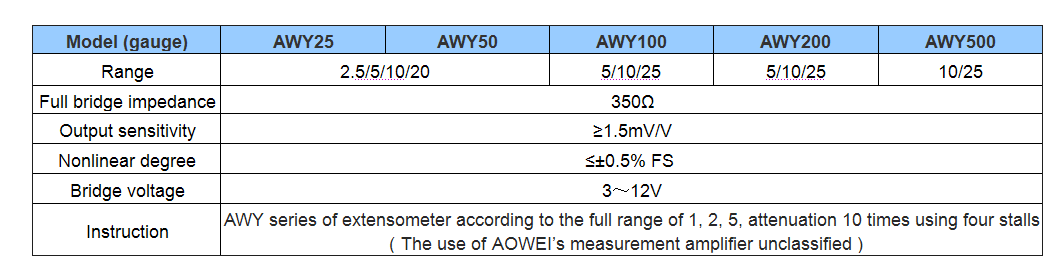

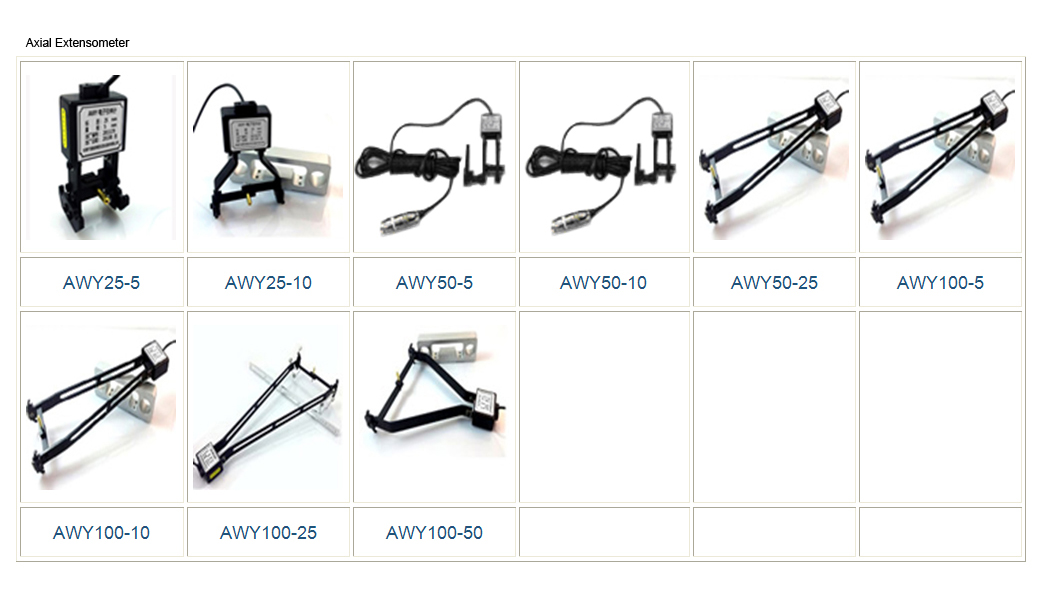

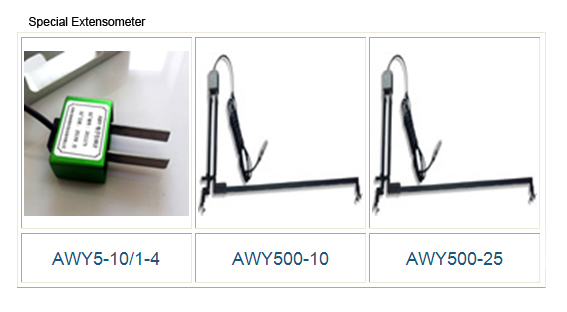

Extensometer specifications:

Gauge (mm):25、50、100、200、400、500

Range (mm):2.5、5、10、15、20、25

Resistance strain gauge

Usage method

* Calibration

a. The calibration of zero mounted extensometer, dial positioning needle.

b. Adjust the zero point of the secondary meter of the measuring amplifier.

c. Rotating calibration dial, the first three degrees of full and back to zero, and then by 2, 4, 6, 8, and the sub point to the full scale (referring to the full range) can be repeated for three times.

* Use

a. Secondary meter connection with measuring amplifier.

b. The extensometer is clamped on the middle position of sample and remove the positioning needle.

c. Adjust the secondary meter zero to start the test.

d. When the required data have been measured at that time, remove the extensometer and plug pins disconnect and secondary meter.

Product Name:High precision extensometer

Applications:

AWY series of extensometer is suitable for measuring various materials in the deformation in the scale distance, such as (metal stretch test, metal steel wire testing machine etc.). It can be used in addition to connecting AOWEI’s board measuring system, but also consist of a deformation measuring system with other measurement system, strain gauge, and two time meter etc..

Metallic materials test

Metallic materials test

Non metallic materials test

Non metallic materials test

Universal testing machine

Universal testing machine

Special testing machine

Special testing machine