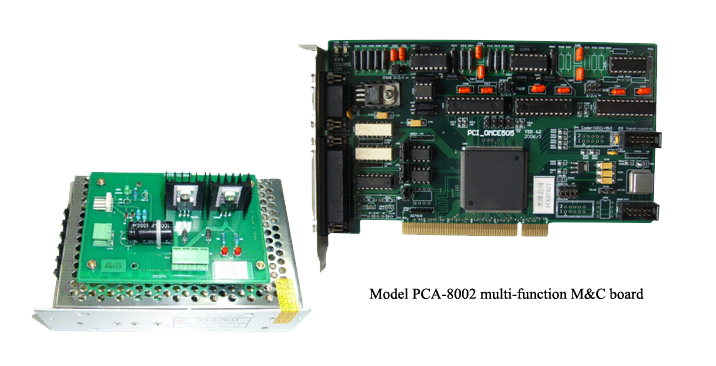

Model PCA-8002 multi-function M&C board

This product uses the computer PCI bus, plug-in design. Single board can be used independently, but also multiple board use, having the characteristics of plug and play, can be flexible according to the requirements of customers and manufacturers to use, and photoelectric coupling technology adopted. Board has 24 A/D conversion, high measurement accuracy. The system in the analog sensor measurement process, bridge voltage and A/D converter uses uniform reference, always stay the same.

Functional characteristics

* This card uses computer bus card, photoelectric isolation design, PCI bus management.

* 3 closed loop control of force, displacement and strain.

* Three channel analog measurement channel and three channel digital sensor measurement channel.

* Simulation measurement: bridge voltage 5V; wide input signal range: 1mv/v、2mv/v、4mv/v、±2.5V、5V; Input a various of sensor measurements(Force sensor, pressure sensor, extensometer, electronic scale type displacement sensor, differential transformer, thermocouple etc.).

* Digital measurement: Input signal frequency >500kHz. Sensor power supply: 5V; can access a variety of sensors(Photoelectric encoder, grating ruler and other, direct measurement).

* Measurement range:1%~100%FS,Measurement accuracy:±0.5%,Control precision: ±0.5%.

* he three way closed loop control. Speed can be adjusted continuously, three control test process random switching, in programmable mode can achieve any running process. And can realize sine wave, triangle wave, trapezoidal wave and arbitrary combination waveform control. Control accuracy is up to ±0.5%.

* Equipped with perfect integrated management of windows device driver and measurement and control software dynamic library, is a comprehensive measurement and control system.

* The utility model can be used alone or can be used in multiple ways to complete the management of a plurality of servo execution units.

* Equipped with PCA-605 electro-hydraulic proportional valve servo amplifier.

Ø The output control signal is received and converted into a power signal which directly drives a bidirectional electro-hydraulic proportional valve to realize the electro-hydraulic servo control function.

Ø Range of power supply: ±12V or ±15V, 100mA.

Ø Output current: 0~±70mA, Output voltage: ±10V

Ø Direct access to the electro-hydraulic servo valve drive coil, drive servo valve operation.

Ø Two light emitting tube indication with output signal direction. 1 path closed loop control channel, any three channel can be set as feedback, to realize of the three way closed loop control. Speed can be adjusted continuously, three control test process random switching, in programmable mode can achieve any running process. And can realize sine wave, triangle wave, trapezoidal wave and arbitrary combination waveform control. Control accuracy is up to ±0.5%.

* Equipped with perfect integrated management of windows device driver and measurement and control software dynamic library, is a comprehensive measurement and control system.

* The utility model can be used alone or can be used in multiple ways to complete the management of a plurality of servo execution units.

* Equipped with PCA-605 electro-hydraulic proportional valve servo amplifier.

Ø The output control signal is received and converted into a power signal which directly drives a bidirectional electro-hydraulic proportional valve to realize the electro-hydraulic servo control function.

Ø Range of power supply: ±12V or ±15V, 100mA.

Ø Output current: 0~±70mA, Output voltage: ±10V

Ø Direct access to the electro-hydraulic servo valve drive coil, drive servo valve operation.

Ø Two light emitting tube indication with output signal direction.

Various types of testing machine

Various types of testing machine